Vibration Analysis

Vibration Analysis for Electric Motors, Pumps, & Other Rotating Equipment

Utilizing our Ampro Electrics Vibration Analysis System, we offer the following predictive maintenance services:

If you are a Maintenance Manager or Maintenance Supervisor, you may want to consider Vibration Analysis and Thermal Imaging as part of your predictive/preventative maintenance program. Vibration Spectrum Analysis is an important part of keeping all of your rotating equipment working at peak performance. This can include equipment such as electric motors, rollers, conveyors, pumps and fans.

A well built program can identify many types of rotating equipment problems before they become catastrophic failures. Problems including things such as:

- Bearing faults

- Imbalance (Fans, rotors, shafts, couplers)

- Mechanical looseness (loose bolts, soft foot, cracked/broken structure)

- Electrical faults in motors (rotor bars, commutators etc)

- Bent shaft

- Resonance and natural frequencies

- Cavitation in pumps

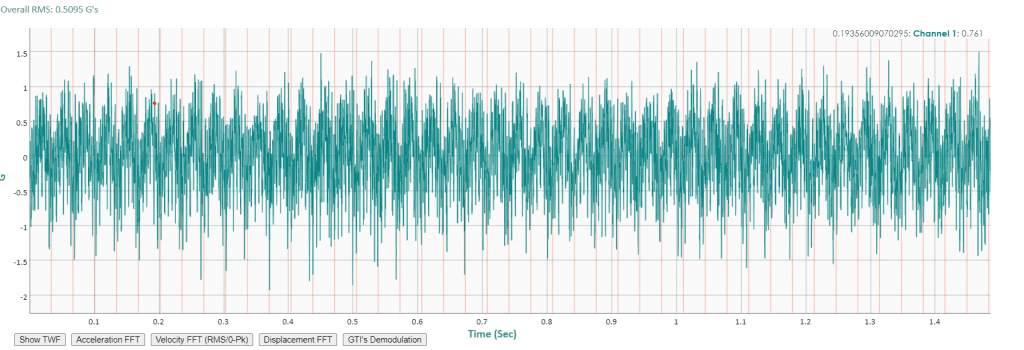

To get started, Ampro Electric will work with your maintenance team to establish a list of your critical rotating equipment. Baseline (acceptance testing) will then be established, and an electronic route will be created so that trending data can be monitored moving forward. A data collection interval will be established based on the needs of our customer and the equipment demands. A qualified Ampro technician will then take routine data pulls and perform spectrum analysis to provide a detailed report on the health of each asset at the agreed intervals. These reports are generated directly out of our GTI software suite and provided in PDF format for easy distribution and viewing to your entire team.

Outside of the predictive maintenance and trending environment, this technology is also used to help diagnose and confirm any of the above issues in situations where confirmation of a suspected mechanical/electrical problem is needed before moving forward with a repair. This confirmation can assist in the decision-making process when large motors or machines that involve cranes or special equipment to remove or repair are being made.

To learn more about the benefits that this technology can provide, please contact us for a live presentation and demonstration at your facility.

Sample Report vibration report edit